Why risk your crane safety when a professional design service is available at an affordable price! Attractively priced design packages are available for a medium capacity workshop for single and double girder cranes. Cranes are designed in accordance to Indian Standard IS: 3177 & 4137.

Whats Required to Initiate the Process

Making steel components

- 1 Molten steel is made by melting iron ore and coke (a carbon-rich substance that results when coal is heated in the absence of air) in a furnace, then removing most of the carbon by blasting oxygen into the liquid. The molten steel is then poured into large, thick-walled iron molds, where it cools into ingots.

- 2 In order to form flat products such as plates and sheets, or long products such as bars and rods, ingots are shaped between large rollers under enormous pressure. Hollow tubes, such as those used to form the latticed booms of large cranes, may be made by bending sheets of steel and welding the long sides together. They may also be made by piercing steel rods with a rotating steel cone.

- 3 The cables used to lift weights are made from steel wires. To make wire, steel is first rolled into a long rod. The rod is then drawn through a series of dies which reduce its diameter to the desired size. Several wires are then twisted together to form a cable.

- 4 Steel arrives at the crane manufacturer and is inspected. It is stored in a warehouse until it is needed. The many different components that will later be assembled into cranes are made using a variety of metalworking equipment. Lathes, drills, and other precision machines are used to shape the steel as required.

Assembling the crane

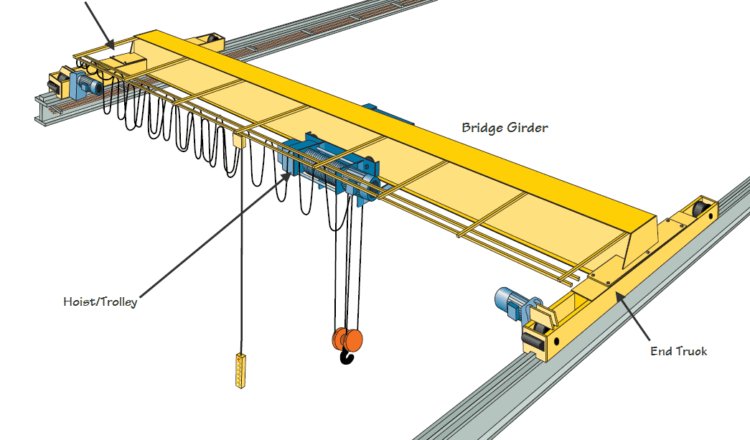

- 5 A crane is put together from the necessary components. As the crane moves along the assembly line, the steel components are welded or bolted into place. The exact procedures followed during this process vary depending on the type of crane being assembled. For a mobile crane, the components are then assembled to a standardized truck or crawler of the appropriate type.

- 6 The assembled crane is tested and shipped. Depending on the size and type of crane, it may be broken down into subsections to be assembled on site. It may also be shipped whole on special large trucks.

Safety is the most important factor to be considered during crane manufacturing. The steel used to make the crane is inspected to An internal tower crane.

ensure that it has no structural flaws that would weaken the crane. Welds and bolts joints are inspected as well