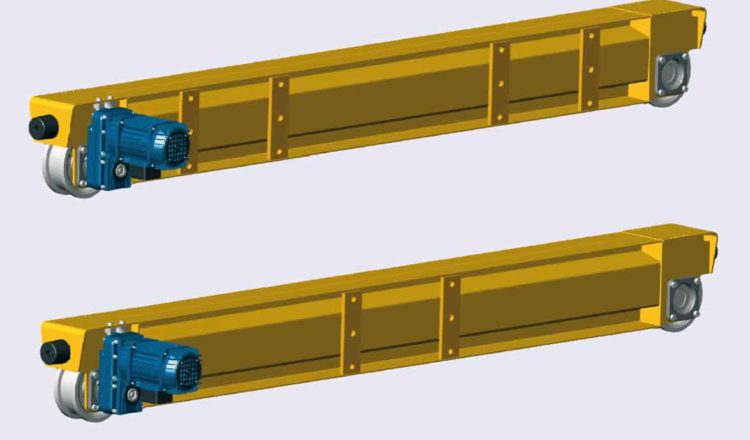

Shubhlaxmi Cranotech LLP end carriages are designed for handling operations on rails, single running speeds from 3.2 to 25 m/m. or two running speeds, from 12,5/3,2 to 80/20 m/m ; operating on single beam crane with capacity up to 20000 Kg. and span up to 25 m., or double beam crane, with capacity up to 40000 Kg. and span up to 27 m.

Shubhlaxmi Cranotech LLP end carriages are designed and built on the principle of modular components assembled together in relation to their specific use, equipped with drive units comprising “DGT” series wheel groups, which in combination with “DGP” series offset geared motors, guarantee accurate alignments for moving structures, control over high traveling speeds, while facilitating installation and maintenance. The end carriages are equipped as standard with two drive units, of which one is a drive unit and the other is idler. However, their special design, due to the use of modular components, allows for flexibility in adapting to different operating needs. The main components of the end carriages are:

Steel frame work in tubular construction

The

end carriage’s structure, in a tubular construction, comprises two

parts built in special sectioned steel, joined together by a continuous

seam welding process. The special construction design also allows the

passage of electrical cables, and the closed body design avoids problems

due to rusting and internal corrosion thereby reducing costly

maintenance to the end carriage’s frame. The bridge crane beams are

securely assembled to the end carriages’ structures by a system of high

resistance traction bolts adopting a stress bearing pin system.